Our Freeze Dryer For Home Statements

Table of ContentsLittle Known Facts About Freezer Temperature.Indicators on Freezer Functions You Need To KnowWhat Does Freeze Dryer Mean?Getting The Freezer Freon To Work

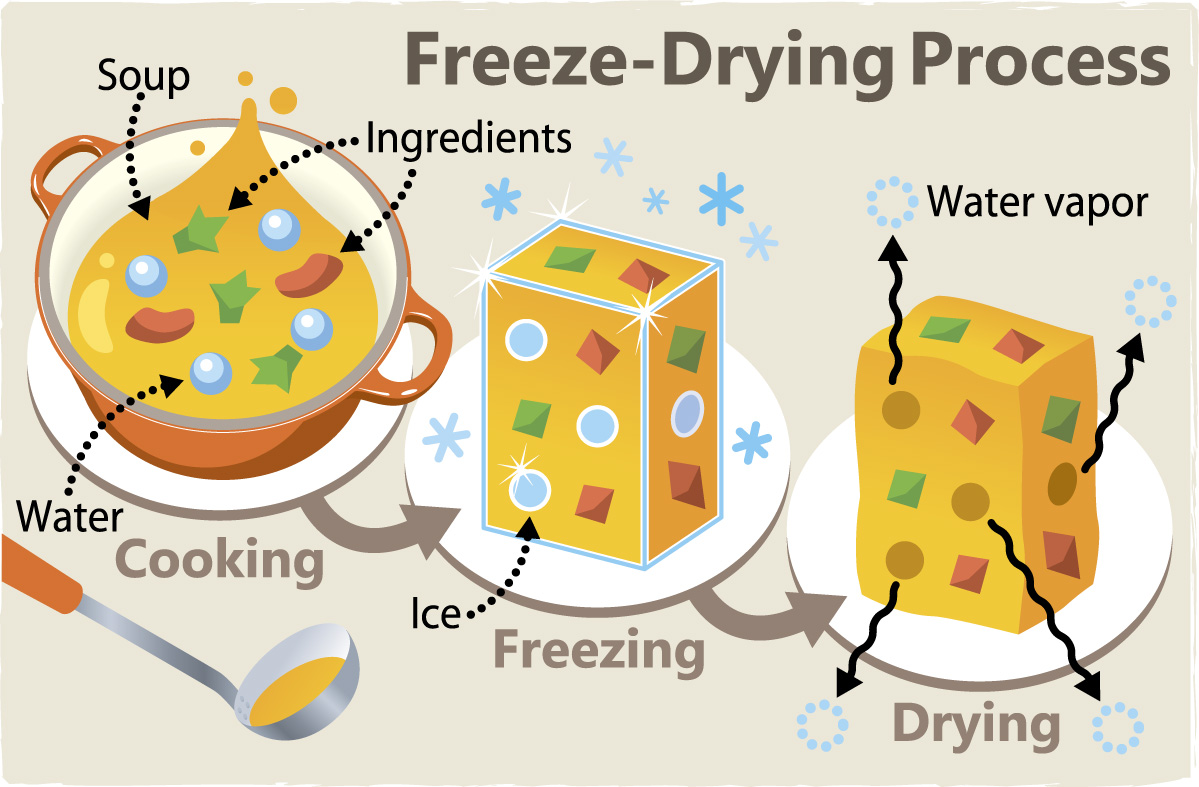

Freeze-drying or lyophilization is a dehydration strategy based on the sublimation of water in a product (, ). This suggests that the item's water material shifts from a solid to a gaseous state or from ice to vapor without experiencing the liquid state (). Freeze-drying is taken into consideration an excellent quality dehydration approach for a number of factors, consisting of (, ): it operates at low temperatures, which adds to protecting a product's dietary worth, taste, appearance, as well as heat-sensitive compoundsfreezing prevents chemical and microbiological processes, which substantially delays the item's deterioration (consequently extending its life span) Raw foods are made up of about 80%95% water, which can be separated into "free" as well as "bound" water.In the freeze-drying procedure, all free water and some bound water should be removed, as well as complimentary water needs to remain frozen whatsoever times. Actually, this is the key difference in between freeze- as well as vacuum-drying and the most difficult step (). The freeze-drying procedure can be divided into three actions (,, ): The product is frequently frozen under air pressure.

Recognized as desorption drying, it's the drying of products to their desired moisture by eliminating the remaining bound water - freezer freon. Freeze-drying need to be carried out in regulated problems that do not melt the water, seeing that the visibility of fluid water might change the product's composition, shape, as well as physical homes ().

Freeze drying takes place in three phases: Freezing Key Drying (Sublimation) Secondary Drying (Adsorption) Appropriate freeze drying out can minimize drying out times by 30% Freezing is the most essential stage of freeze drying out, and there are lots of techniques for it. Cold can be done in a freezer, a chilled bath (shell freezer) or on a rack in the freeze clothes dryer (freezer freon).

The Buzz on Freeze Dryer

Freeze drying is most convenient to accomplish using huge ice crystals, which can be generated by slow-moving freezing or annealing. With organic products, when crystals are as well big they may break the cell walls, as well as that leads to less-than-ideal freeze drying outcomes.

About 95% of the water in the product is gotten rid of in this phase. Primary drying out can be a slow-moving procedure. Way too much heat can modify the framework of the material. Freeze drying out's last stage is secondary drying out (adsorption), during which the ionically-bound water particles go to this site are removed. By raising the temperature level greater than in the key drying out phase, the bonds are damaged in between the material and also the water particles.

After the freeze drying out process is complete, the vacuum cleaner can be damaged with an inert gas before the material is sealed. A lot of materials can be dried out to 1-5% recurring dampness.

The Of Freeze Dryer

The basic concept in freeze-drying is sublimation, the change from a strong directly into a gas. Similar to evaporation, sublimation happens when a molecule gains enough energy to break without the particles around it. Water will certainly sublime from a strong (ice) to a gas (vapor) when the molecules have sufficient power to break free but the problems aren't right for a liquid to create (deep freeze unfreezer).

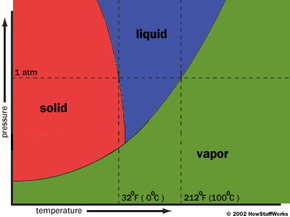

For a material to take any particular phase, the temperature level and stress must be within a certain variety. The chart below shows the essential pressure and also temperature values of different more stages of water.

06 atmospheres (ATM MACHINE), the water is cozy sufficient to thaw, yet there isn't sufficient stress for a liquid to develop. This is specifically what a freeze-drying equipment does.

When you secure the chamber and begin the procedure, the machine runs the compressors to reduce the temperature level in the chamber. The material is frozen solid, which divides the water from every little thing around it, on a molecular degree, although the water is still existing. Next off, the maker switches on the vacuum cleaner pump to require air out of the chamber, decreasing the air pressure below.

The Ultimate Guide To Deep Freeze Unfreezer

Since the stress is so reduced, the ice transforms straight into water vapor. The water vapor condenses onto the freezing coil in solid ice type, in the exact same way water condenses as frost on a cool day.

Yes, they are undoubtedly among the more pricey food conservation techniques. It's vital to know that freeze drying is different than dehydrating.

The various other day a buddy asked me if I'm as delighted concerning it as I was when I initially got it. Well, I'm a lot more excited actually, and also afterwards discussion, I went out and acquired a 2nd device! To be sincere, I had not been very thrilled concerning the freeze dryer in the beginning.